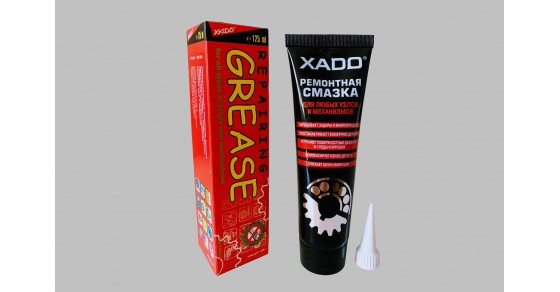

XADO Repairing grease, 125 ml

ProductID XA 30203-3820653544738914414

Net Weight 0.120 kg.

Availability:

By request

Shipping: 2 business days

Producer

XADO ®

XADO Repairing grease, 125 ml

APPLICATION: XADO Grease Repairing is designed to protect and restore units and mechanisms operating under heavy loads The grease forms a new cermet layer on friction surfaces: the parts grow in volume, restore their original geometry. It is also applied for restoring of high-speed and heavy loaded units which cannot be repaired in a regular way.Contains REVITALIZANT®

ADVANTAGES: Rejects heat from friction areas; Eliminates scratches and microcracks; Can stand high rotation speed; Reduces noise and vibration; Compensates 80% wear; Eliminates corrosion and protects units from hostile environment.

TECHNICAL INFO: The patented formula of this up-to-date grease is based on a composition of XADO revitalizant and EP complex (Extreme Pressure).STEPS:1. Remove the old grease. 2: Fill 1/2 of unit volume with XADO Grease “Repairing”. 3: If assembles require periodical grease changing you should use XADO Grease “Protective” later on.

NOTE: Do not use for new assemblies and parts! The grease is especially effective for repair of quite worn bearings (up to 10,000 rpm)

Recommendations of mechanics:From the experience of revitalization of water pumps.As you know, water pumps in foreign cars are not filled with the grease while operating. That is why you should dismantle the pump, drill a hole in its body and remove the old grease with the help of compressed air. Then add a small amount of XADO Grease “Repairing” (1-2 ml) into the cavity of the pump body and fill half of the remaining cavity with XADO Grease “Restoring”. Seal the hole with any heat-resistant sealing material. Lathe the pump for 20 minutes in both sides, then you can install the pump into the car.

The term “REVITALIZATION” (from Latin “vita” – life) literally translated means “returning to life”. The discovery of the revitalization phenomenon is based on unique physical and chemical processes, which, under specific conditions, can occur in the friction zone. In short, their essence consists of the following: during mechanical operation, excessive loads occur in the friction areas. At extremely heavy loads, excess destructive energy is released. But if we introduce a unique building material – a revitalizant – into the friction zone, then the energy released by the friction, will actually bind new material to the friction surface instead of destroying the material surface.

This has always been the case until the phenomenon of REVITALIZATION was discovered, when scientists found that it was possible to reversing the process of wear by restoring the worn-out surface! It turned out that conditions could be created when the affected part is able to restore its surface thickness and size to its initial dimensions. To create such favourable conditions, it is necessary to introduce a specially synthesized substance – XADO revitalizant into the friction zone. It contains the building material for the new surface and a unique energy activator, which enables the excess friction energy to be harnessed in order to create a new matrix – in fact, a brand new surface.

The key features of the part’s surface before and after revitalization are as follows: increase in micro hardness (kg/micro metre2) from 65-280 to 650-750 range, after treatment; the roughness coefficient (Ra) before revitalization was 0.9-2.1, and after treatment it is 0.06; and above all a dramatic increase in corrosion-resistance characteristics.

No an XADO will not damage your engine. XADO revitalizants are completely soluble in the oil and do not change the viscosity of the properties of the oil in any way. Remember XADO is self-regulating. As soon as the original worn surface has been repaired, the friction factor drops dramatically, and the XADO activation energy will also decrease. The process then stabilizes, and at some point, the energy will drop to a point where cermet growth will stop completely. Besides, using too much is just a waste of money.

A superhard coating is formed as a result of the revitalizant’s application. Can the engine be rebored, if necessary? - This is a common question from car owners, and we would like to set their minds at ease. The metal-ceramic coating is formed to the depth of 10–30 microns, and the boring tool can remove tenths of a 1 mm. Also, But do you really need conventional major overhaul? The unique ability to restore the original geometry of engine parts will allow you to avoid these labour-intensive and expensive repairs. For instance, the repair of the sleeve assembly can be reduced to just replacing damaged piston rings or replacing rings that have completely lost elasticity, replacing a burnt-out piston, etc. In other words, you would only need a “face-lift” repair.

It is not possible for the metal-ceramic layer to peel off in operation. A reciprocal diffusion of metal and metal carbides to the depth of 10–30 μm (micrometer) takes place. There is no distinct border between the initial surfaces and metalceramic, so there are no conditions for the metal-ceramic layer to “peel-off”.